CCA Capabilities

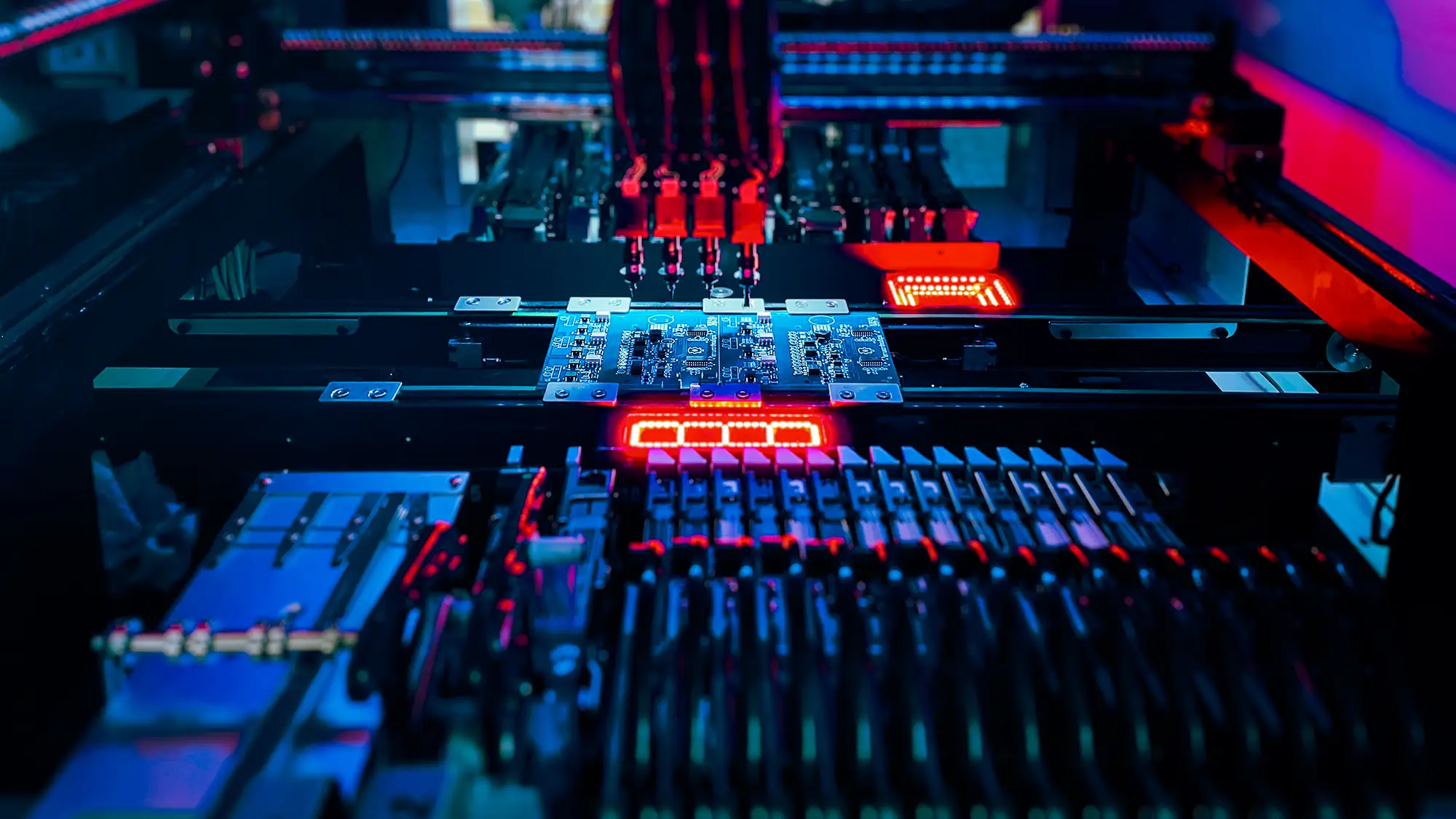

- 4 fine-pitch surface mount lines (Europlacer equipment).

- Automated and semi-automated plated through-hole and mixed technology.

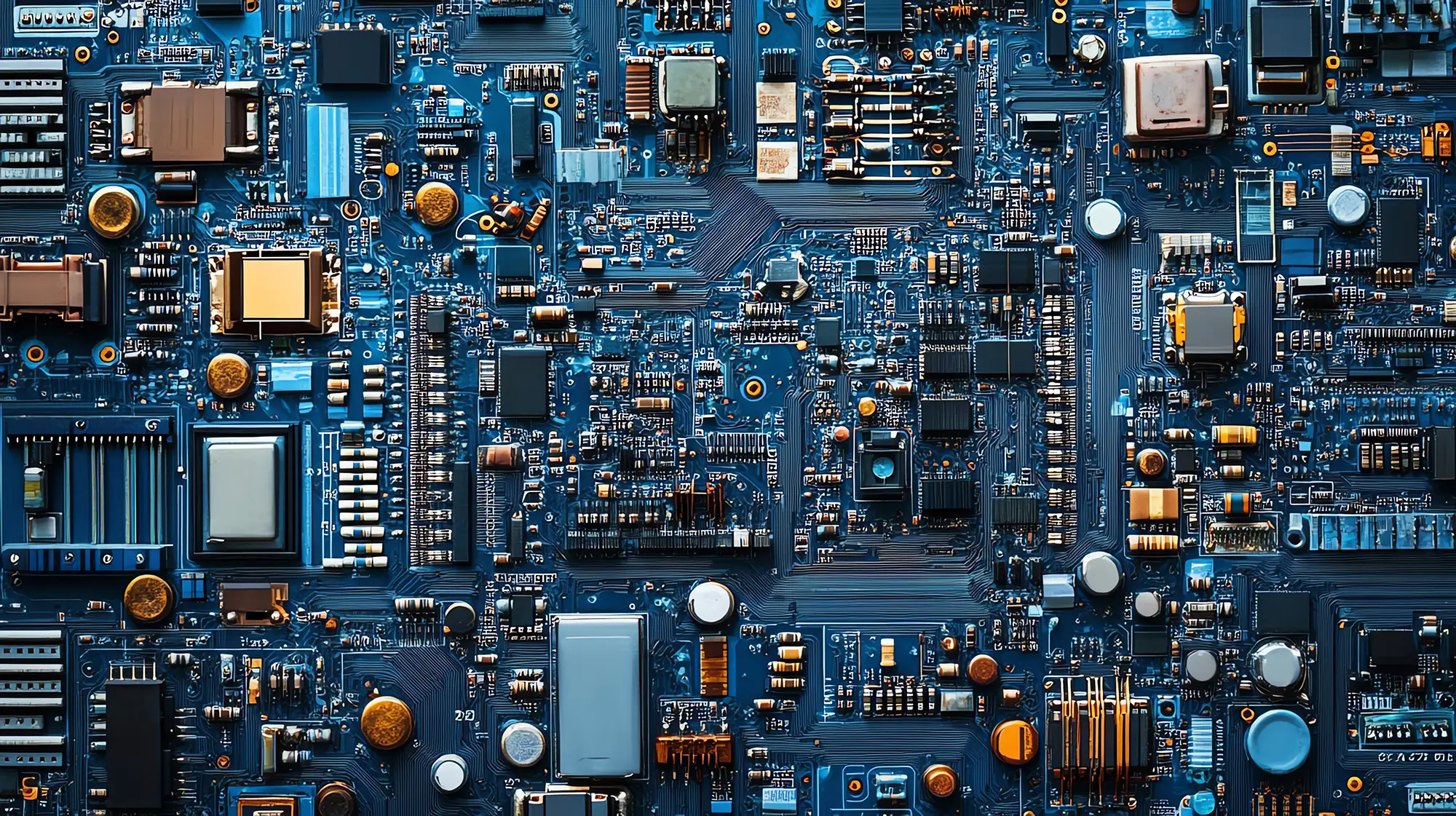

- Smallest BGA pitch 0.3mm.

- Package sizes down to 01005 form factor.

- Large form factor PCBAs.

- Column grid arrays and ceramic standoffs.

- High-density PCBAs.

- 264 8mm feeder lanes per SMT equipment.

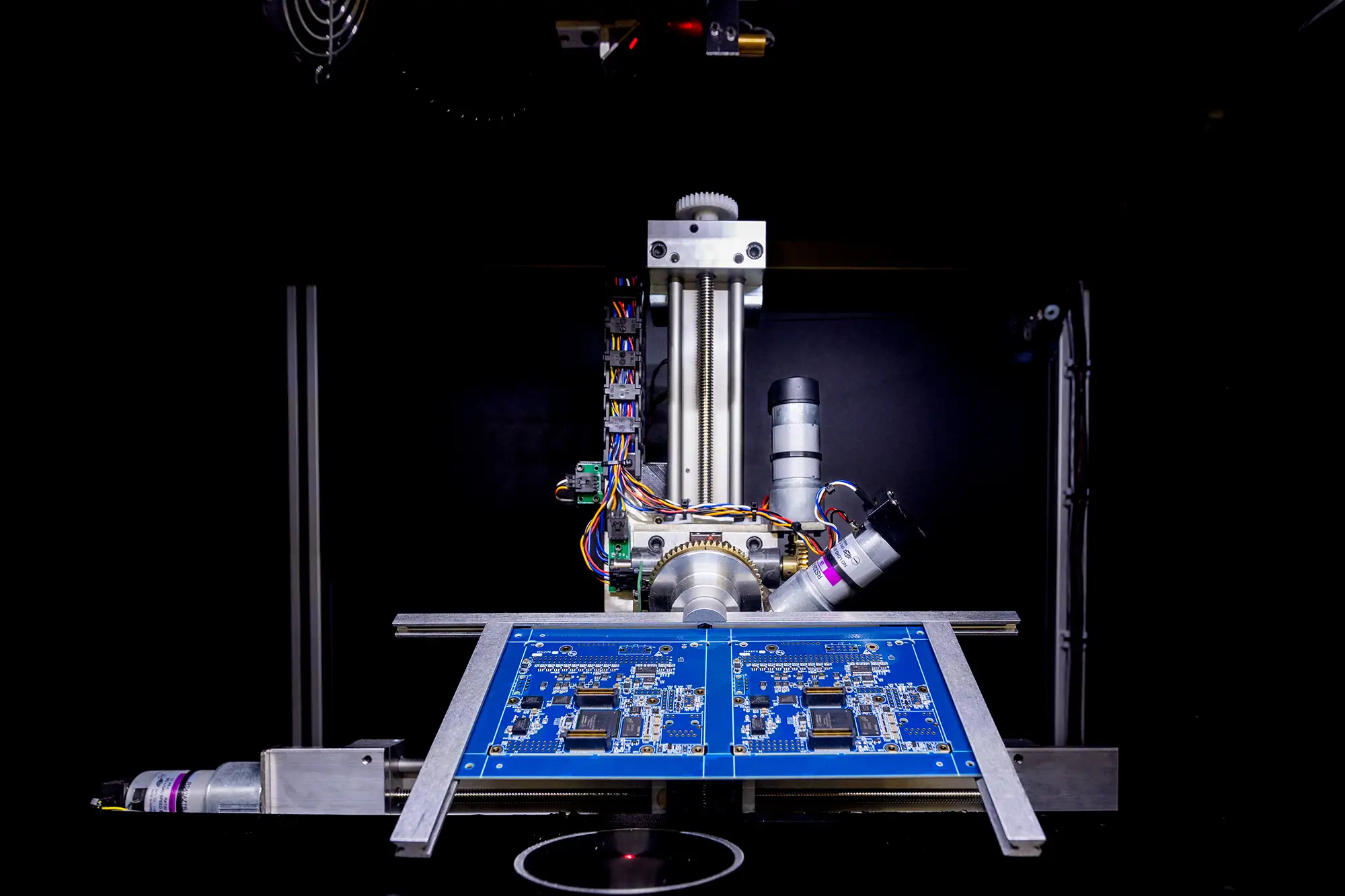

- 2-D & 3-D paste inspection measurement technology.

- 4 inline stencil printers.

- Inline automated 3-D solder paste inspection.

- Max panel size 450mm X 500mm.

- Flex and rigid-flex manufacturing on various finishes, such as HASL, ENIG and ENEPIG.

- RF, analog, high-speed, and digital circuits on rigid-flex and copper core substrates.

- Typical lot sizes of 1-500 pieces.

- Reflow profiling.

- Large field of view (LFOV) x-ray inspection.

- Aqueous cleaning with deionized (DI) water.

- Ionograph testing.

- Schematic capture and printed circuit board (PCB) layout support.

- Flexible wave solder systems with selective solder capabilities.

- Conformal coating capabilities for silicone, acrylic, urethane, and parylene.